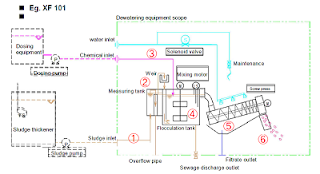

1) Sludge in storage tank is transferred to measuring tank by sludge pump.

2) Sludge flow rate will be adjusted by the liquid level controller in the measuring tank before moving into flocculation tank.

The rest of the sludge flows back to the storage tank.

3) Inject polymer flocculants into flocculation tank and make it fully mixed with sludge until dry solids become big flocs.

4) Flocs flow into the screw press after mixing process.

5) Big flocks are thickened by gravity in the thickening zone and move to the dewatering zone.

6) In a dewatering zone, as space between moving rings and fixed rings gets smaller.

And under the big pressure from back-pressure plate, sA large proportion of liquid is squeezed out.

At last, sludge cake is pressed out from outlet.

For more information or enquiry, please contact Environmech Sdn. Bhd.

Contact us: http://www.environmech.com/p/contact-us.html

Website: www.Environmech.com