The world's top air suspension high-speed motor professional manufacturer.

Hiturbine (Korea) INC is a famous air suspension centrifugal manufacturer in Korea located in Qingzhou city, Hiturbine suspension technology (Jiangsu) Co., Ltd is a Joint Venture between Korea and China that invested 10,000,000 USD in Yixing city, Jiangsu Province, China. And the manufacturing area is 22256 square meters.

Our company is focused on air suspension technology, after 15 years of research and development, We developed the air suspension blower and compressor. They would save 30-50% more energy than other Roots blowers & compressors. Our output is about 5000 sets/year. Customers are welcome to visit our factory and discuss business. High technology, High quality, High efficiency, and Best after-sale service.

Air Bearing Blower & Compressor

Type: single

Pressure(mmAq):4000,6000,8000,10000

Material: Aluminum

Flow Direction: Centrifugal

Pressure: Low Pressure

Certification: CE

Trademark: HiTurbine

Transport Package: Wood Carton

Origin Korea, China

Industry Application for Hi-Turbine

The Hi-Turbine centrifuge has been used globally. It has been applied in large-scale industries in Japan, the United States, Belgium, Uzbekistan, Vietnam, and other countries. It has eliminated the traditional centrifuge and compressor commonly used at present. It is the energy-saving and environmental protection centrifuge technology in the future.

Manufacturing process

Daily maintenance

Maintenance process: Filter cotton

1) 2 layers of filter cotton, maintenance-free, just replace the filter cotton.

2) Use Medium Filter to Filter, ash removal rate increased by more than 95%, effectively reducing the damage of impurities in the air to the machine, improving the service life.

3) Convenient means of exchange

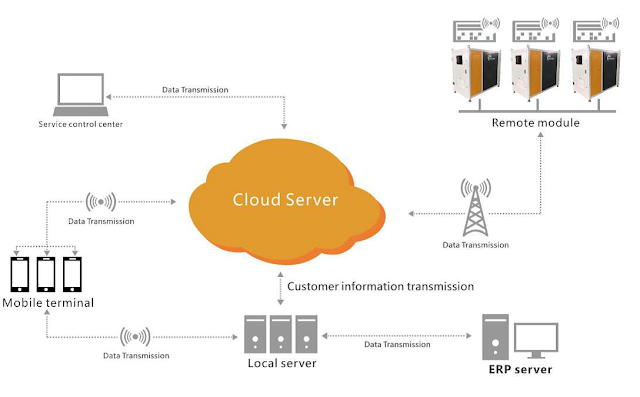

Hi-Turbine cloud service system

1)Through wireless communication components, the system transmits various data of mechanical state information in field operation, including speed, temperature, pressure, flow rate and power, to the headquarters of the manufacturer at any time.

2)The manufacturer's computer data centre analyzes and processes the running state of the fan at any time.

The use of wireless communication technology, so that we can provide users with secure remote services at the headquarters.

Hi-Turbine air suspension blower 5 core advantages

1) Energy-saving and high efficiency: compared with the traditional roots blower, the ultra-high-speed motor with air suspension bearing can improve the energy-saving efficiency by more than 20%-30%.

2) Oil-free maintenance-free: high-speed motor and impeller are directly connected through air suspension bearing, running without any friction, no lubricating oil, no high maintenance cost, no secondary pollution to the environment, is an environmental protection product.

3) Variable frequency: frequency conversion range: 45% - 100%

4) Low noise: below 80 decibels on average

5) Small size: 50% smaller than roots blower of the same specification

Photos

For more information or enquiry, please contact Environmech Sdn. Bhd.

Shandong Tianrui Heavy Industry Co., Ltd. was founded in 2008, located in Weifang High-tech Zone. It is a high-tech enterprise engaged in research and development of magnetic levitation technology and rock drilling machinery.

Tianrui has a leading R&D team in the industry. The company has 167 patents and three kinds of products of well-known brands in Shandong.

We have passed ISO 9001:2008 Quality Control System, ISO14001 Environment Management System, OHSAS18001 Professional Health Safety Control System, Measurement Management and intellectual property management system certification, and CE Certification.

According to the evaluation of China Hi-tech Industrialization Research Association has concluded that the energy-saving and noise-reducing effect of the Maglev Turbo Blower reaches the international advanced level.

Product introduction

The maglev turbo blower developed by Tianrui Heavy Industry is a kind of high-tech green energy-saving environmental products. Adopting core technologies, including advanced magnetic suspension bearings, three-dimensional flow impellers, high-speed permanent magnet synchronous motors, high-efficiency frequency converter, intelligent monitoring and control.

When starting, It is suspended at first and then rotated, without friction, without lubrication, a direct connection between turbine and rotor, and zero transmission loss.

Compared with Roots blower, it can save 30%-40% energy and reduce noise to less than 80 dB.

It is widely used in sewage treatment, aquaculture, steel, cement, food, brewing, textile, petrol chemistry, thermal power plant and other fields.

Working principle

The active magnetic levitation bearing system is the core system of the magnetic levitation blower. The motor rotor is fixed between two radial magnetic levitation bearings and two thrust magnetic levitation bearings.

The position of the rotor is detected by the position sensor, and the position signal is reflected to the main controller in real-time. When the rotor is deflected, the main controller will return the rotor to the correct position by the way of adjusting the magnetic force of the magnetic bearing.

Overall Structure

Active magnetic suspension bearing

With controllable electromagnetic force, it can provide motor rotor with non-contact and non-wear support, which has no mechanical friction and lubrication, low noise, and so on.

Hydrodynamic impeller

The centrifugal impeller of high strength aluminum alloy processed by 5-axis precision machine tools is designed by a three-dimensional flow method, which maximizes the efficiency of the centrifugal impeller and has a long service life.

High-efficiency Frequency Converter

It is used to regulate the speed of PMSM, which can be monitored by integrated HMI.

High-speed Permanent magnet motor

Adopt compact stator and filling permanent magnet rotor, which is of high rotating speed, high efficiency and long service life.

Control system

It uses 256-bit LCD-TFT touch screen and 800*480 DPI high resolution widescreen to provide users with a variety of communication interfaces.

It has an anti-surge (SURGE) protection function and maximizes product safety. Provide a variety of modes of operation.

Application Industry

Municipal and industrial sewage treatment

It is mainly used to aerate the sewage tank, so that the bio activator in the sewage treatment tank can fully contact the substances in the sewage, thereby achieving the purpose of decontamination.

Material gas transportation

Cement plant, chemical, food and other industries: It is used for pneumatic conveying of industrial raw materials, dust, food raw materials, etc.

Industrial applications

Papermill, brewing industry, textile industry, dairy processing industry, thermal power industry, etc.

Aquaculture

Blowing air into the bottom of the aquaculture ponds increases the oxygen content in the ponds in order to increases the survival rate of the aquatic products.

Performance comparison

Compared with Roots Blower

Dimension Drawing

The size:

For equipment with 110kw and less than 110kw(L*W*H):

1900*1300*1730mm;

For equipment with 150kw and more than 150kw(L*W*H):

2100*1200*1800mm

Size requirements for installation:

For environmental requirements, the indoor floor is flat, with no dust or very little dust.

It is recommended that the cement floor be paved with ceramic tile or floor paint.

Environmech Sdn. Bhd.

since 2012 Co. Reg. No: (1007069-M)

For more information or enquiry, please contact Environmech Sdn. Bhd.

Contact us: http://www.environmech.com/p/contact-us.html

Website: www.Environmech.com